Modular Design

We Specialize in Design and Manufacture of Bevel Gears, Hypoid Gears, Spur Gears, Helical Gears, Forging Gears, Gearboxes and Auto Parts.

Highly Customized Production

We Specialize in Design and Manufacture of Bevel Gears, Hypoid Gears, Spur Gears, Helical Gears, Forging Gears, Gearboxes and Auto Parts.

READ MORE

NEWS

Profile

COMPANY

Minchen gear was established in 1968. The most experienced, specialized developer

and manufacturer of bevel gears in Taiwan. The entire factory is equipped with GLEASON machines

and KLINGELNBERG machines, such as hypoid cutter sharpeners, cutter inspection machines, hypoid

generators, hypoid testers, and hypoid lappers, gear grinding which can carry out any cutting

methods developed by GLEASON.

READ MORE

APPLICATION

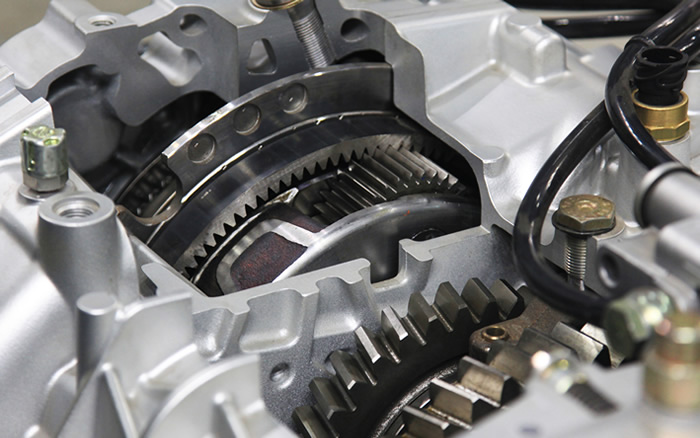

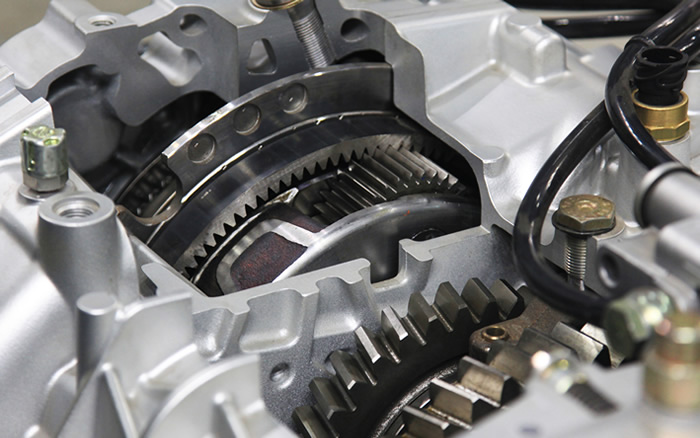

AUTOMOTIVE

Gear production is not dependent on a single industry. Gears are used almost everywhere and are essential for any transmission and the steering for all bodies. Minchen team has widely applied the gearing technology to steering、differential、transmission shaft、turning and milling parts in the automotive industry.

In the automotive industry, gears are fundamental to the operation of virtually every type of vehicle. They are used in transmission systems to transfer power from the engine to the wheels, enabling vehicles to move. Depending on the gear ratio, they allow the vehicle to travel at various speeds and provide the torque necessary for tasks like climbing hills or towing.

MINCHEN GEAR's high-quality gears are integral to these systems. With precision manufacturing processes and strict quality control measures, MINCHEN GEAR ensures its gears meet the exacting standards required by the automotive industry. This results in reliable, durable gears that deliver exceptional performance.

Moreover, MINCHEN GEAR's products are not just limited to vehicle transmissions. Gears are also used extensively in other automotive systems, such as steering systems, where they help translate the rotation of the steering wheel into the turning of the wheels.

READ MORE

APPLICATION

MACHINE TOOLS

Gear production is not dependent on a single industry. Gears are used almost everywhere and are essential for any transmission and the steering for all bodies. Minchen team has widely applied the gearing technology to power turret、ATC、hollow rotary table、indexing plate、curved/straight clutch、milling head and various reducing mechanism in the machine tool industry.

Machine tools are essential equipment used in various industrial processes such as milling, drilling, cutting, and grinding. The efficiency and precision of these machines heavily rely on the gears that transmit power and motion throughout the system. This is where Minchen Gear comes in.

Minchen Gear offers a wide array of gear types, including spur gears, helical gears, bevel gears, worm gears, and rack and pinion gears. These gears are available in various sizes, configurations, and materials, allowing us to cater to the diverse needs of the machine tools industry.

Our gears are known for their exceptional precision, durability, and resistance to wear and tear. They are designed to operate at high speeds and withstand heavy loads, ensuring optimal performance and extended service life for machine tools. Additionally, our gears undergo rigorous quality control measures to guarantee consistent and reliable performance in demanding industrial environments.

By integrating Minchen Gear's products into their machine tools, manufacturers can benefit from improved efficiency, reduced downtime, enhanced accuracy, and increased productivity. Our gears facilitate smooth power transmission, minimize vibration and noise, and maintain the overall stability of the machine, resulting in higher-quality outputs and reduced maintenance costs.

READ MORE

APPLICATION

ATV

Gear production is not dependent on a single industry. Gears are used almost everywhere and are essential for any transmission and the steering for all bodies. Minchen team has widely applied the gearing technology to differential、transmission shaft and various forging parts in the ATV industry.

ATVs are versatile off-road vehicles widely used for recreational activities, agricultural work, and other outdoor pursuits. Gears within ATVs are essential components responsible for transferring power from the engine to the wheels, allowing for controlled acceleration, speed, and maneuverability.

Minchen Gear offers a diverse selection of gears specifically designed for ATV applications. Our gears are meticulously engineered to deliver exceptional performance, durability, and efficiency, ensuring smooth power transmission in challenging off-road conditions.

We provide a variety of gear types suitable for ATVs, including spur gears, helical gears, bevel gears, and planetary gears. These gears can be customized in terms of size, material, tooth profile, and configuration to meet the specific requirements of different ATV models and applications.

Our gears are designed to handle the demands of off-road environments encountered by ATVs. They are manufactured with precision, ensuring accurate tooth profiles, proper meshing, and minimal backlash. This results in smooth operation, reduced noise, and vibration, enhancing the overall riding experience.

READ MORE

APPLICATION

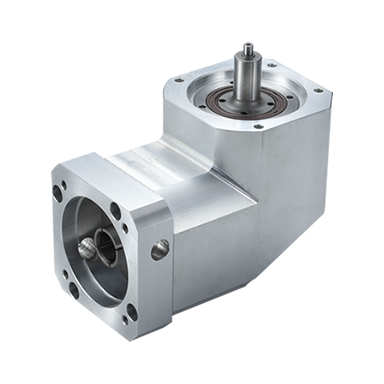

ROBOTS

Gear production is not dependent on a single industry. Gears are used almost everywhere and are essential for any transmission and the steering for all bodies. Minchen team has widely applied the gearing technology to industrial robot manipulator and high ratio reducing mechanism in the robot industry.

Robots are advanced machines designed to perform tasks autonomously or assist humans in various industries, such as manufacturing, logistics, healthcare, and more. Gears are integral components within robots, enabling the transmission of power and motion to different robotic joints, actuators, and mechanisms.

Minchen Gear offers a diverse selection of gears specifically designed for robotics applications. Our gears are meticulously engineered to deliver exceptional performance, precision, and durability, ensuring smooth and reliable operation in robotic systems.

We provide a variety of gear types suitable for robots, including spur gears, helical gears, bevel gears, worm gears, and planetary gears. These gears can be customized in terms of size, material, tooth profile, and configuration to meet the specific requirements of different robotic applications.

Our gears are designed to handle high torque loads, ensuring efficient power transmission and precise motion control in robots. They are manufactured with precision, ensuring accurate tooth profiles, proper meshing, and minimal backlash, resulting in smooth and accurate movement of robotic components.

READ MORE

APPLICATION

FORKLIFT

Gear production is not dependent on a single industry. Gears are used almost everywhere and are essential for any transmission and the steering for all bodies. Minchen team has widely applied the gearing technology to differential、transmission shaft and milling parts in the forklift industry.

Forklifts are essential material handling equipment widely used in warehouses, distribution centers, and industrial facilities. Gears are integral components within forklifts, responsible for transmitting power from the engine to the wheels and other operational mechanisms.

Minchen Gear offers a diverse selection of gears that are specifically designed for forklift applications. Our gears are engineered with precision, durability, and efficiency in mind, ensuring optimal performance and reliability in demanding material handling operations.

We provide a variety of gear types suitable for forklifts, including spur gears, helical gears, bevel gears, and planetary gears. These gears can be customized to meet specific requirements such as torque, speed, load capacity, and noise reduction.

Our gears are designed to handle the heavy loads and frequent start-stop operations typically encountered in forklifts. They are manufactured with precise tooth profiles, proper meshing, and minimal backlash, ensuring smooth and reliable power transmission throughout the forklift's drivetrain.

READ MORE

APPLICATION

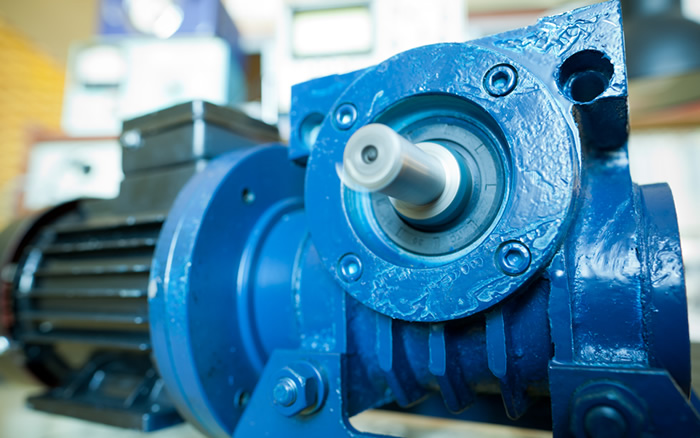

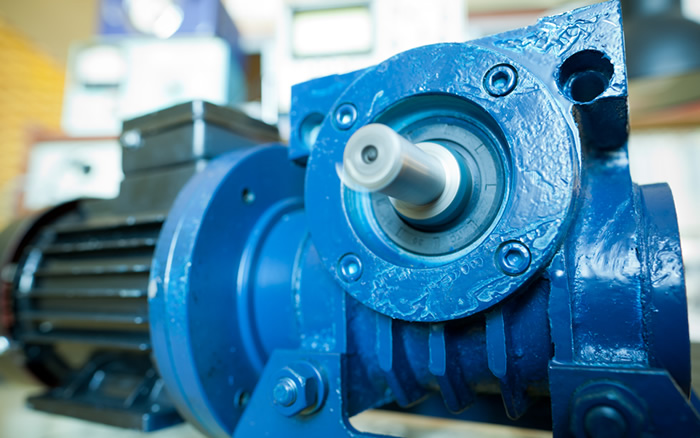

SPEED REDUCER

Gear production is not dependent on a single industry. Gears are used almost everywhere and are essential for any transmission and the steering for all bodies. Minchen team has widely applied the gearing technology to bevel gear reducer series and high ratio reducing mechanism in the reducer industry.

Speed reducers, also known as gearboxes, play a critical role in machinery and equipment by reducing the input speed from a power source (such as an electric motor) and transmitting the torque to the driven load. Gears within the speed reducer are responsible for adjusting the speed and torque output to match the requirements of the specific application.

Minchen Gear offers a diverse range of gears that are well-suited for speed reducers. Our products are engineered to deliver optimal performance, durability, and efficiency, ensuring smooth power transmission and precise speed control.

We provide a variety of gear types suitable for speed reducers, including spur gears, helical gears, bevel gears, worm gears, and planetary gears. These gears are manufactured with utmost precision, ensuring accurate tooth profiles, proper meshing, and minimal backlash. We also offer different gear materials, such as steel alloys, to suit various applications and load requirements.

Our gears are designed to handle high torque and operate at different gear ratios, allowing for versatile speed reduction capabilities. Whether your application requires high torque at low speeds or high-speed reduction with lower torque, Minchen Gear's products can be customized to meet your specific needs.

READ MORE

APPLICATION

AGRICUlTURAL MACHINERY

Gear production is not dependent on a single industry. Gears are used almost everywhere and are essential for any transmission and the steering for all bodies. Minchen team has widely applied the gearing technology to differential、transmission shaft and various forging parts in the agricultural industry.

Agricultural machinery plays a vital role in modern farming, facilitating tasks such as tilling, planting, harvesting, and irrigation. Gears are essential components in these machines, responsible for transmitting power and motion to different agricultural implements.

Minchen Gear offers a wide range of gears that are well-suited for agricultural machinery. Our products are meticulously engineered to deliver exceptional performance, durability, and efficiency, ensuring reliable operation even in demanding farming conditions.

We provide a diverse selection of gear types suitable for agricultural machinery, including spur gears, helical gears, bevel gears, worm gears, and planetary gears. These gears can be customized in terms of size, material, and configuration to meet the specific requirements of different agricultural applications.

Our gears are designed to handle high torque loads, ensuring efficient power transmission to drive various agricultural implements, such as tillers, plows, seeders, harvesters, and irrigation systems. They are manufactured with precision, ensuring accurate tooth profiles, proper meshing, and minimal backlash, resulting in smooth operation and reduced wear.

READ MORE

APPLICATION

OUTBOARD ENGINE/MOTORS

Gear production is not dependent on a single industry. Gears are used almost everywhere and are essential for any transmission and the steering for all bodies. Minchen team has widely applied the gearing technology to the forward/reverse gears for different horsepower in the outboard engine industry and various turning、milling and forging parts.

Outboard motors play a crucial role in powering and controlling boats, providing propulsion and maneuverability on the water. Gears are an integral part of these motors, as they enable the transfer of power from the engine to the propeller, converting rotational motion into thrust.

Minchen Gear produces high-quality gears that are well-suited for use in outboard motors. Our gears are engineered to deliver optimal performance and efficiency, ensuring smooth power transmission and reliable operation.

We offer a range of gear types that can be used in outboard motors, including spur gears, helical gears, and bevel gears. These gears are manufactured with precision to meet the specific requirements of the marine industry, taking into account factors such as load capacity, torque, and durability.

Our gears are designed to withstand the harsh marine environment, where exposure to water, salt, and other elements can pose challenges. We utilize advanced materials and coatings that provide excellent corrosion resistance, ensuring the longevity and reliability of our gears even in marine applications.

READ MORE

APPLICATION

POWER TOOLS

Gear production is not dependent on a single industry. Gears are used almost everywhere and are essential for any transmission and the steering for all bodies. Minchen team has widely applied the gearing technology to manual grinders and garden tool in the power tool industry.

Power tools are essential equipment used in construction, woodworking, metalworking, and various other industries. Gears within power tools are responsible for transmitting power from the motor to the working mechanism, allowing for efficient cutting, drilling, grinding, or other operations.

Minchen Gear offers a diverse range of gears specifically designed for power tool applications. Our gears are meticulously engineered to deliver exceptional performance, durability, and efficiency, ensuring smooth power transmission and reliable operation in demanding working conditions.

We provide a variety of gear types suitable for power tools, including spur gears, helical gears, bevel gears, and worm gears. These gears can be customized in terms of size, material, tooth profile, and configuration to meet the specific requirements of different power tool models and applications.

Our gears are designed to handle high torque loads and high-speed operation, ensuring efficient power transmission and precise control in power tools. They are manufactured with precision, ensuring accurate tooth profiles, proper meshing, and minimal backlash, resulting in smooth and reliable operation.

READ MORE

APPLICATION

GEARBOXES

Gear production is not dependent on a single industry. Gears are used almost everywhere and are essential for any transmission and the steering for all bodies. Minchen team has widely applied the gearing technology in various industries, such as automobile、agricultural machinery、machine tool、AGV and automated production line.

Gearboxes are essential mechanical devices that transmit and control power in various machinery and equipment. Gears within the gearbox are responsible for adjusting speed, torque, and direction of rotation, enabling the desired output for different applications.

Minchen Gear offers a diverse selection of gears specifically designed for gearboxes. Our gears are meticulously engineered to deliver exceptional performance, durability, and efficiency, ensuring smooth and reliable power transmission.

We provide a variety of gear types suitable for gearboxes, including spur gears, helical gears, bevel gears, worm gears, planetary gears, and more. These gears can be customized in terms of size, material, tooth profile, and configuration to meet the specific requirements of different gearbox applications.

Our gears are designed to handle high torque loads, ensuring efficient power transmission and minimizing energy losses within the gearbox. They are manufactured with precision, ensuring accurate tooth profiles, proper meshing, and minimal backlash, resulting in smooth operation and reduced noise and vibration.

READ MORE APPLICATION

AUTOMOTIVE

MACHINE TOOLS

ATV

ROBOTS

FORKLIFT

SPEED REDUCER

AGRICUlTURAL MACHINERY

OUTBOARD ENGINE/MOTORS

POWER TOOLS