APPLICATION

- HOME

- APPLICATION

- MACHINE TOOLS

MACHINE TOOLS

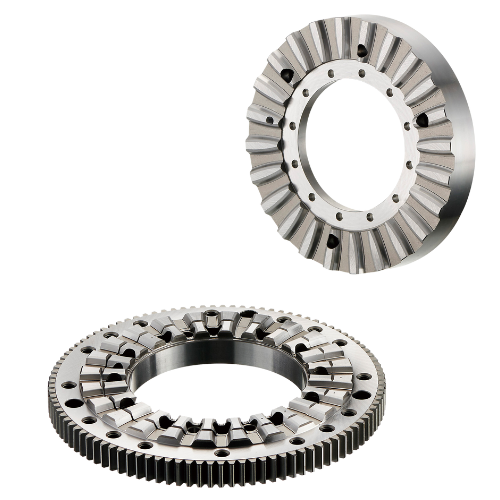

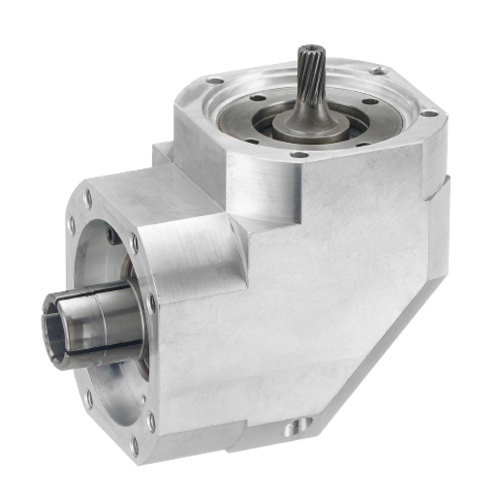

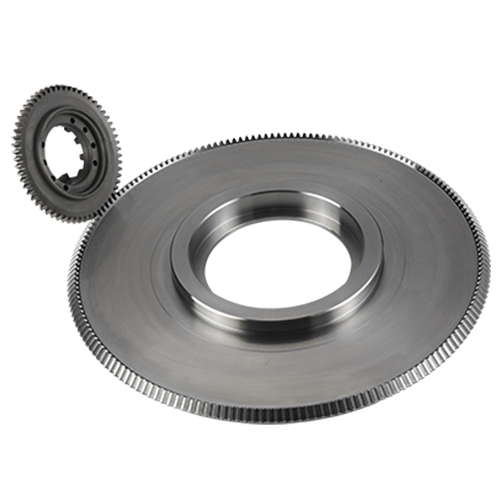

Gear production is not dependent on a single industry. Gears are used almost everywhere and are essential for any transmission and the steering for all bodies. Minchen team has widely applied the gearing technology to power turret、ATC、hollow rotary table、indexing plate、curved/straight clutch、milling head and various reducing mechanism in the machine tool industry.

Machine tools are essential equipment used in various industrial processes such as milling, drilling, cutting, and grinding. The efficiency and precision of these machines heavily rely on the gears that transmit power and motion throughout the system. This is where Minchen Gear comes in.

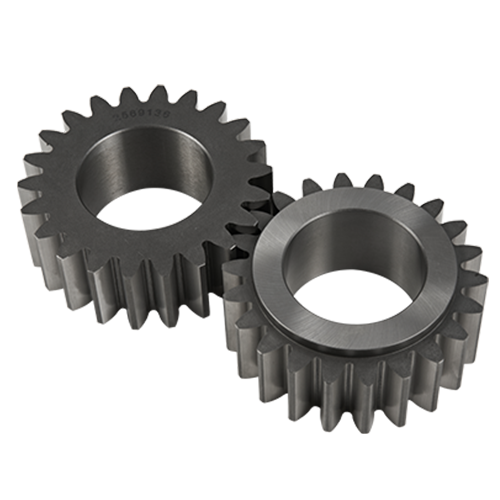

Minchen Gear offers a wide array of gear types, including spur gears, helical gears, bevel gears, worm gears, and rack and pinion gears. These gears are available in various sizes, configurations, and materials, allowing us to cater to the diverse needs of the machine tools industry.

Our gears are known for their exceptional precision, durability, and resistance to wear and tear. They are designed to operate at high speeds and withstand heavy loads, ensuring optimal performance and extended service life for machine tools. Additionally, our gears undergo rigorous quality control measures to guarantee consistent and reliable performance in demanding industrial environments.

By integrating Minchen Gear's products into their machine tools, manufacturers can benefit from improved efficiency, reduced downtime, enhanced accuracy, and increased productivity. Our gears facilitate smooth power transmission, minimize vibration and noise, and maintain the overall stability of the machine, resulting in higher-quality outputs and reduced maintenance costs.

Machine tools are essential equipment used in various industrial processes such as milling, drilling, cutting, and grinding. The efficiency and precision of these machines heavily rely on the gears that transmit power and motion throughout the system. This is where Minchen Gear comes in.

Minchen Gear offers a wide array of gear types, including spur gears, helical gears, bevel gears, worm gears, and rack and pinion gears. These gears are available in various sizes, configurations, and materials, allowing us to cater to the diverse needs of the machine tools industry.

Our gears are known for their exceptional precision, durability, and resistance to wear and tear. They are designed to operate at high speeds and withstand heavy loads, ensuring optimal performance and extended service life for machine tools. Additionally, our gears undergo rigorous quality control measures to guarantee consistent and reliable performance in demanding industrial environments.

By integrating Minchen Gear's products into their machine tools, manufacturers can benefit from improved efficiency, reduced downtime, enhanced accuracy, and increased productivity. Our gears facilitate smooth power transmission, minimize vibration and noise, and maintain the overall stability of the machine, resulting in higher-quality outputs and reduced maintenance costs.