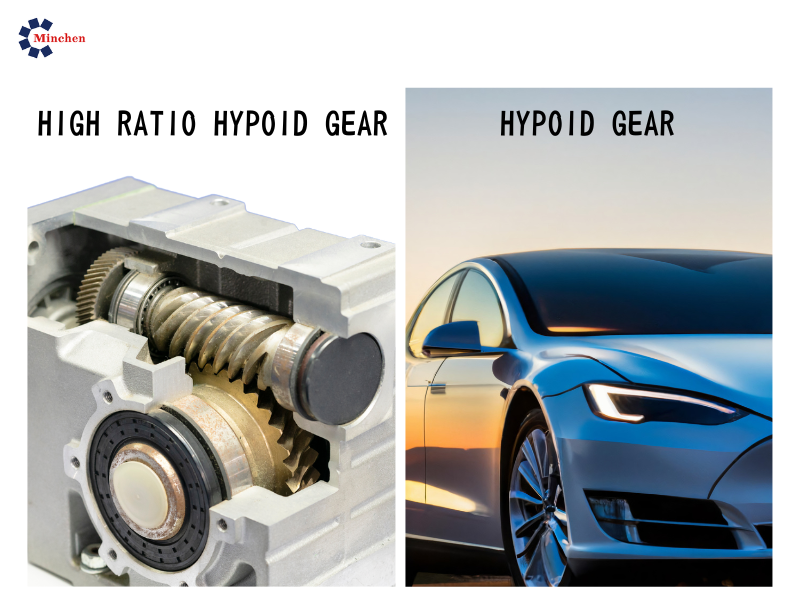

Minchen's Precision Gearing Solutions: HIGH RATIO HYPOID GEAR for Speed Reducers and HYPOID GEAR for Cars

In the intricate world of machinery and automobiles, where precision and reliability are non-negotiable, Minchen, a name synonymous with excellence in gearing solutions, steps into the limelight. With a commitment to precision engineering and a legacy of innovation, Minchen has been providing the automotive and industrial sectors with advanced gearing solutions that redefine performance standards. In this article, we will delve into two remarkable offerings from Minchen's arsenal: the HIGH RATIO HYPOID GEAR designed for speed reducers and the versatile HYPOID GEAR used in cars.

Exploring Minchen's HIGH RATIO HYPOID GEAR

Understanding HIGH RATIO HYPOID GEAR

Before we dive into the intricacies of Minchen's HIGH RATIO HYPOID GEAR, let's demystify what this gear truly represents. At its core, a HIGH RATIO HYPOID GEAR is a type of gearing mechanism renowned for its efficiency and precision. It finds its prominence in mechanical systems where the ratio between input and output speeds is high. This feature makes it particularly suitable for applications that require a significant reduction in rotational speed with minimal power loss. To grasp the significance of high gear ratios, imagine an application where a small input rotation should result in a substantial output rotation or torque - this is where HIGH RATIO HYPOID GEARS shine.

Minchen's Expertise

Minchen's reputation as a pioneer in the precision gear manufacturing field is well-earned. The company's expertise in crafting HIGH RATIO HYPOID GEAR showcases a remarkable fusion of cutting-edge technology and meticulous craftsmanship. These gears are precision-engineered to meet the stringent demands of industries where accuracy and efficiency are non-negotiable. Minchen's commitment to quality is reflected in every gear produced, making them a vital component in various industrial applications.

Applications

The versatility of HIGH RATIO HYPOID GEAR is truly remarkable, finding applications across a spectrum of industries. These gears serve as the backbone of machinery in applications such as speed reducers, conveyors, and industrial manufacturing systems. In essence, they are the unsung heroes of countless industries where smooth power transmission and reliability are of paramount importance.

In speed reducers, these gears facilitate the process of converting high-speed rotation into slow and high-torque motion. The HIGH RATIO HYPOID GEAR's ability to handle high gear reductions with precision makes it a vital component in systems where controlled motion and energy efficiency are key.

Moreover, in conveyor systems, where materials or products need to be transported with precision and consistency, Minchen's HIGH RATIO HYPOID GEAR ensures that every rotation is a step closer to an efficient operation. It's not just about moving materials; it's about doing so with reliability, thereby minimizing downtime and maintenance costs.

Conclusion of the HIGH RATIO HYPOID GEAR:

In the world of precision engineering, HIGH RATIO HYPOID GEAR is the unsung hero, working behind the scenes to ensure smooth, efficient, and reliable operation in various industrial applications. With Minchen's commitment to precision and excellence, these gears stand as a testament to what can be achieved when innovation and engineering excellence combine.

The Versatility of HYPOID GEAR in the Automotive Industry

Introduction to HYPOID GEAR

Now, let's shift our focus to the automotive industry, where Minchen's contribution is no less than extraordinary. At the heart of many automotive systems lies a type of gear known as HYPOID GEAR. These gears play a pivotal role in ensuring that vehicles run smoothly and efficiently.

What distinguishes HYPOID GEARS from other gear types is their unique configuration. Unlike standard bevel gears, where the axes of the input and output shafts intersect, HYPOID GEAR axes are offset from each other, allowing for more versatile applications. The hypoid shape of these gears is designed to facilitate torque transfer between non-intersecting shafts. This unique design is crucial for the efficient operation of certain automotive components.

Minchen's Role in Automotive Engineering

Minchen's contribution to the automotive industry is notable for its precision and quality. As a trusted supplier of HYPOID GEARS, Minchen ensures that these critical components are designed and manufactured to meet the rigorous demands of modern vehicles.

The automotive industry demands components that can withstand the rigors of daily use and provide optimal performance. This is where Minchen's expertise in precision gear manufacturing comes into play. The company's dedication to engineering excellence ensures that every HYPOID GEAR it produces contributes to the reliability, efficiency, and safety of vehicles.

Applications in Cars

The application of HYPOID GEAR in cars is diverse and multifaceted. One of the most critical applications is in the drivetrain, where these gears enable the transfer of power from the engine to the wheels. The efficiency of this power transfer directly impacts a vehicle's acceleration, fuel economy, and overall performance.

Additionally, HYPOID GEARS are integral components of a car's differential. The differential is a crucial part of the drivetrain that allows wheels to rotate at different speeds when turning, ensuring smooth and stable handling. The precision and reliability of Minchen's HYPOID GEARS are essential for the proper functioning of this critical automotive component.

In essence, these gears contribute to the stability and control of a vehicle, enhancing its safety and performance. They are the hidden champions that work silently to ensure a smooth and efficient driving experience.

Conclusion of HYPOID GEAR in the Automotive Industry:

Minchen's role in the automotive sector is nothing short of remarkable. The precision and reliability of HYPOID GEAR are crucial for the performance, stability, and safety of vehicles. Through its commitment to engineering excellence, Minchen has become a trusted partner in the automotive industry, ensuring that every vehicle equipped with its gears is a testament to quality and precision.

Engineering Excellence and Quality Assurance

The Engineering Process

Minchen's journey to precision gear manufacturing excellence involves a multifaceted engineering process. Each gear, whether it's a HIGH RATIO HYPOID GEAR for a speed reducer or a HYPOID GEAR for an automobile, undergoes a meticulous design and engineering phase. The use of cutting-edge technology and advanced software ensures that every gear is tailored to meet the unique requirements of its intended application.

From the initial concept to the final design, Minchen's engineers leave no stone unturned. The company's commitment to precision is evident in its ability to design gears that operate with minimal friction, noise, and maximum efficiency. The engineering process is a marriage of creativity and precision, resulting in gears that meet and often exceed industry standards.

Quality Assurance

Minchen's gears undergo stringent quality control measures to ensure they meet the highest standards of performance and durability. Advanced metrology tools are used for inspection, guaranteeing that each gear meets precise tolerances. This commitment to quality is a testament to Minchen's dedication to providing precision engineering solutions that work seamlessly in the most demanding applications.

From material selection to the final inspection, every step of the manufacturing process is marked by Minchen's unwavering commitment to quality and precision. The gears are engineered and tested to withstand the rigors of their respective applications, whether in speed reducers, conveyors, or automobiles.

Minchen's dedication to precision engineering and quality assurance sets the company apart as a leader in the field of precision gear manufacturing. It's not just about producing gears; it's about producing gears that redefine what is possible in terms of efficiency, reliability, and precision.

Customer-Centric Approach and Global Reach

Customer Collaboration

Minchen's customer-centric approach is marked by collaboration and a deep understanding of the unique requirements of its clients. Whether it's a manufacturer of industrial machinery looking for gears to enhance their system's performance or an automotive company seeking the perfect components for their vehicles, Minchen takes the time to listen, understand, and collaborate.

The company's ability to customize solutions based on the specific needs of its customers is one of its core strengths. This approach ensures that the gears produced are not just components but essential parts of a larger system, working seamlessly to deliver the desired results.

Global Impact

Minchen's impact is not confined to its home base; it's a global presence that reverberates across industries worldwide. The precision gears manufactured by Minchen enhance machinery and automotive systems internationally. They are the unsung heroes in critical applications where precision, reliability, and efficiency matter the most.

From aerospace to automotive, from industrial machinery to renewable energy, Minchen's gears have left an indelible mark. Their role in enhancing the performance of machines and vehicles translates into progress and innovation on a global scale. Minchen's global reach is not just about selling gears; it's about driving industries forward.

Conclusion

In a world where precision engineering and reliability are paramount, Minchen's HIGH RATIO HYPOID GEAR for Speed Reducers and HYPOID GEAR for Cars stand as exemplars of excellence. These gears, whether working silently behind the scenes in industrial applications or contributing to the performance and safety of vehicles, are a testament to what can be achieved when innovation and engineering excellence combine.

Minchen's dedication to precision engineering, its unwavering commitment to quality assurance, and its customer-centric approach have set the company on a trajectory of global impact. Minchen's gears are not just components; they are the foundation of precision and reliability in the machines and vehicles that drive progress and innovation across industries.

As we navigate a future where innovation and precision will continue to define progress, Minchen's HIGH RATIO HYPOID GEAR and HYPOID GEAR will remain steadfast in their role as the unsung heroes of precision engineering.

Discover more about Minchen's precision gearing solutions and their global impact here.