Understanding Zero Bevel Gears: A Comparison with Straight Bevel and Spiral Bevel Gears

Introduction:

In the realm of mechanical transmission, selecting the right type of gear is crucial for optimizing performance, durability, and noise reduction. Zero Bevel Gears offer a unique combination of features from both straight bevel gears and spiral bevel gears, making them an attractive option for many applications. This article will compare these three types of gears, highlighting the advantages of Zero Bevel Gears and why they might be the best choice for your manufacturing needs.

What Are Zero Bevel Gears?

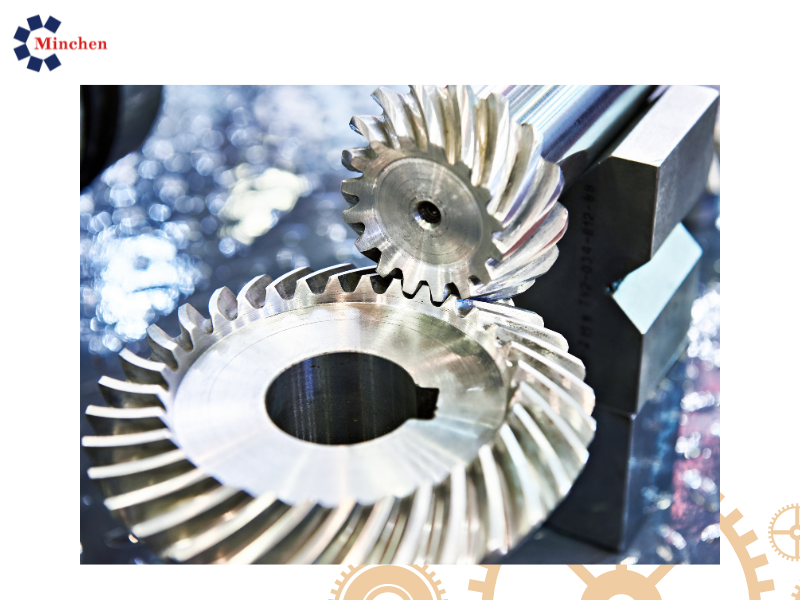

Zero Bevel Gears are a specialized type of bevel gear with a zero-degree spiral angle. This means that while they share some characteristics with straight bevel gears, they also incorporate the smoother engagement and contact properties typical of spiral bevel gears.

Comparison of Gear Types:

Straight Bevel Gears:

- Design: Straight bevel gears have straight teeth that converge on an axis. Their simple design makes them relatively easy to manufacture.

Advantages:

- Cost-Effective: Generally cheaper to produce due to simpler manufacturing processes.

- High Load Capacity: Suitable for applications requiring high torque and low-speed operation.

Disadvantages:

- Noise and Vibration: The straight teeth cause more noise and vibration during operation.

- Wear and Tear: Higher stress concentration at the point of contact can lead to faster wear.

Spiral Bevel Gears:

- Design: These gears have curved teeth set at an angle, allowing for gradual engagement and smoother operation.

Advantages:

- Smooth Operation: The curved teeth provide gradual engagement, reducing noise and vibration.

- Durability: Better load distribution across the teeth reduces wear.

Disadvantages:

- Complex Manufacturing: More complex to produce, leading to higher costs.

- Alignment Sensitivity: Requires precise alignment during installation to avoid operational issues.

Zero Bevel Gears:

- Design: Zero Bevel Gears have straight teeth like straight bevel gears but feature a curved profile similar to spiral bevel gears. The spiral angle is zero degrees.

Advantages:

- Smoother Engagement: Combines the simplicity of straight teeth with the smooth engagement of curved teeth, reducing noise and vibration.

- Balanced Load Distribution: Better load distribution across the teeth enhances durability and reduces wear.

- Versatile Applications: Suitable for high-precision applications where both strength and smooth operation are required.

Disadvantages:

- Complexity: More complex to manufacture than straight bevel gears, potentially increasing production costs.

- Installation Precision: Requires careful alignment during installation to achieve optimal performance.

Applications of Zero Bevel Gears:

Zero Bevel Gears are particularly suited for use in:

- Automotive Differentials: Ensuring precise power transmission and quiet operation.

- Aerospace: Where high precision and reliability are critical.

- Robotics: Enabling smooth and accurate motion control.

- Industrial Machinery: Offering durable performance in high-load and high-speed applications.

Why Choose Minchen Gear Co., Ltd. for Zero Bevel Gears?

Minchen Gear Co., Ltd. excels in producing high-quality Zero Bevel Gears, leveraging advanced manufacturing technology and rigorous quality control processes. Our expertise ensures that you receive gears that meet the highest standards of precision and performance.

Conclusion:

Zero Bevel Gears combine the best features of straight bevel and spiral bevel gears, providing a balance of strength, smooth operation, and durability. For manufacturers requiring reliable and efficient gears, Zero Bevel Gears from Minchen Gear Co., Ltd. offer an ideal solution.

Call to Action:

If your manufacturing needs demand high-quality Zero Bevel Gears, contact Minchen Gear Co., Ltd. today. Let us help you enhance the efficiency and performance of your machinery with our precision-engineered gears. Visit our website or reach out directly to discuss your specific requirements with our experts.