Essential Gears for Machine Tools: Precision Solutions from Minchen Gear Co., Ltd.

Introduction:

Machine tools are the backbone of modern manufacturing, providing the precision and efficiency needed to shape, cut, and form materials into finished products. These versatile machines include lathes, milling machines, drilling machines, grinding machines, and CNC machining centers, each playing a crucial role in the production of components across various industries. Machine tools rely heavily on gears to perform their operations accurately and reliably, making the quality of these gears paramount to the overall performance of the equipment.

Overview of Common Machine Tools:

- Lathes: Used for rotating workpieces and removing material with cutting tools, lathes are essential for manufacturing cylindrical parts, such as shafts, screws, and spindles.

- Milling Machines: Equipped with rotating cutting tools, milling machines are used to cut, shape, and drill parts. They are versatile and can handle a variety of tasks, including slotting, grooving, and complex surface contouring.

- Drilling Machines: Specially designed to drill holes, these machines are used in various applications, from creating simple through-holes to complex drilling operations in different materials.

- Grinding Machines: These machines use abrasive wheels to finish surfaces to high precision and smoothness. They are crucial in applications where tight tolerances and surface finish are critical.

- CNC Machining Centers: These are advanced, computer-controlled machine tools capable of performing multiple functions like milling, drilling, and turning with high precision and automation.

Gears Used in Machine Tools:

Gears play an integral role in the operation of these machine tools, enabling them to perform with precision, reliability, and efficiency. Some of the key gears commonly used include:

- Spiral Bevel Gears: Essential for transmitting power between intersecting shafts at various angles, providing smooth and quiet operation in machine tools.

- Helical Gears: Used for their ability to handle higher loads and transmit power more smoothly compared to spur gears, making them ideal for heavy-duty machine tools.

- Spur Gears: Commonly found in machine tools for applications where simplicity and high efficiency are required.

Minchen Gear Co., Ltd. Product Offerings:

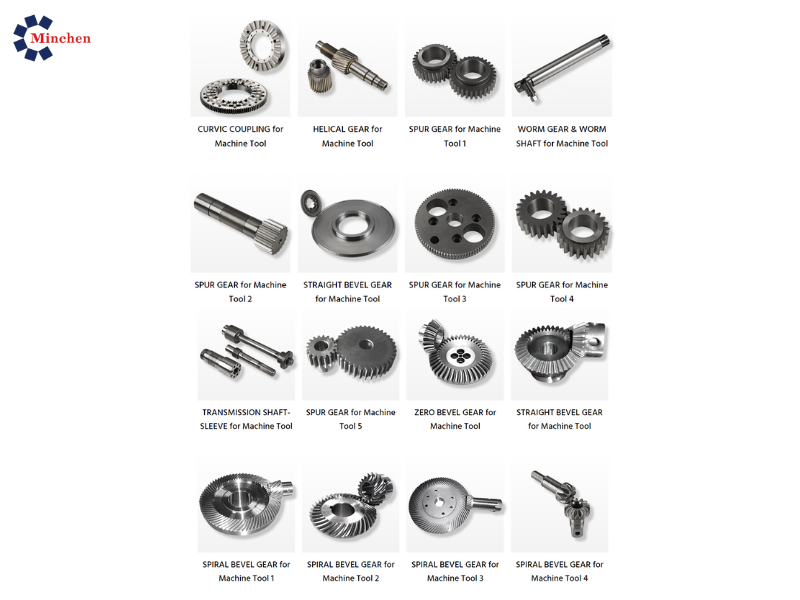

At Minchen Gear Co., Ltd., we offer a comprehensive range of high-quality gears specifically designed for the demanding requirements of machine tools. Our product lineup includes:

- Curvic Couplings: These precision couplings are used for high-torque, high-precision applications, ensuring reliable and accurate alignment in machine tool spindles and indexing mechanisms.

- Helical Gears: Ideal for applications that require high load capacity and smooth, quiet operation, our helical gears are engineered to deliver exceptional performance in various machine tools, including milling machines and CNC machining centers.

- Spur Gears: Known for their simplicity and efficiency, spur gears from Minchen are perfect for applications where high-speed, high-precision gear transmission is essential, such as in drilling and turning equipment.

- Worm Gears: Our worm gears provide excellent speed reduction and high torque output in a compact design, making them suitable for use in equipment like grinding machines and other precision-driven applications.

- Straight Bevel Gears: These gears are used in applications requiring intersecting shafts, such as in gearboxes for machine tools, offering reliable power transmission and high durability.

- Transmission Shafts: Complementing our gear products, Minchen’s transmission shafts are designed to meet the highest standards of precision and strength, ensuring smooth and efficient power transfer in machine tools.

- Zero Bevel Gears: Combining the best features of straight bevel and spiral bevel gears, our zero bevel gears offer smooth operation with minimal noise and vibration, making them ideal for high-precision machinery.

- Spiral Bevel Gears: Perfect for applications that require the transmission of power between intersecting axes with high efficiency and low noise, our spiral bevel gears are essential for CNC machinery and other advanced machine tools.

We also offer custom ODM services, providing tailored gear solutions that meet the specific requirements of your machine tool designs. Our advanced manufacturing capabilities and commitment to quality ensure that our gears are not just components, but key contributors to the success of your machinery.

Why Choose Minchen Gear Co., Ltd.?

Choosing Minchen Gear Co., Ltd. means partnering with a leader in gear manufacturing that understands the unique demands of machine tools. Our gears are made using advanced CNC machines and cutting-edge technology, ensuring that each gear meets the highest standards of precision and durability. Whether you are manufacturing new machine tools or maintaining existing ones, our comprehensive range of gear products can help you achieve the performance and reliability you need.

Contact Us Today:

If you are a machine tool manufacturer or user looking for high-quality gears, Minchen Gear Co., Ltd. is here to assist. We provide customized gear solutions and ODM services to meet your exact specifications. Contact us today to discuss your needs and find out how we can support your gear requirements for machine tools. Visit our website or reach out directly to speak with our experts.