HYPOID GEAR for Vehicle 2

Product Description

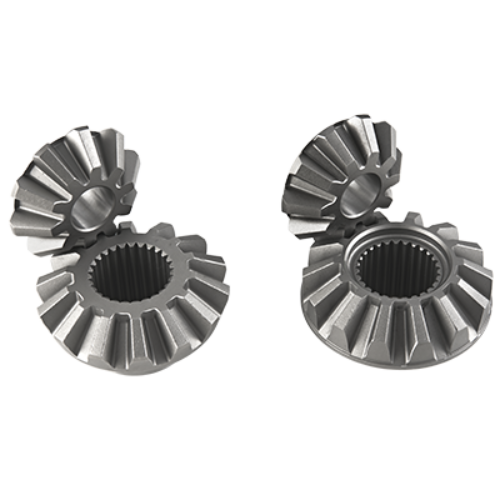

Hypoid forged gears are advanced power transmission components designed for automotive applications that require high efficiency, durability, and smooth operation. Unlike conventional bevel gears, hypoid gears feature an offset between the drive and pinion axes, allowing for larger gear contact areas and higher torque transmission. This design enhances load-carrying capacity, reduces noise and vibration, and ensures smooth power transfer, even under demanding conditions.

Forged from high-strength alloy steel, hypoid gears provide exceptional durability and wear resistance, making them ideal for vehicles operating under high loads and variable speeds. These gears are commonly used in automotive differentials, where precise power distribution is essential for vehicle performance, stability, and handling.

Minchen Gear Co., Ltd. leverages cutting-edge forging and machining technology to produce hypoid gears that meet the rigorous demands of the automotive industry. Our hypoid forged gears are engineered to deliver superior performance in passenger cars, SUVs, trucks, and other vehicles, ensuring reliability and long-lasting operation in challenging environments.

Forged from high-strength alloy steel, hypoid gears provide exceptional durability and wear resistance, making them ideal for vehicles operating under high loads and variable speeds. These gears are commonly used in automotive differentials, where precise power distribution is essential for vehicle performance, stability, and handling.

Minchen Gear Co., Ltd. leverages cutting-edge forging and machining technology to produce hypoid gears that meet the rigorous demands of the automotive industry. Our hypoid forged gears are engineered to deliver superior performance in passenger cars, SUVs, trucks, and other vehicles, ensuring reliability and long-lasting operation in challenging environments.

One stop shopping

MINCHEN GEAR is ODM and OEM company based entirely in Taiwan. We are not only the producer, but also the designer of industry renown products. Excellence and precision are taken seriously at MINCHEN and therefore we have been an employer of choice for many PHDs and gear experts.

Along with our advanced equipment, this deep field of expertise let’s us strictly control the manufacturing process; from material control to cutting precision to finished products. 90% of manufacturing processes are in house. Whether it is reverse engineering or customized gear products, MINCHEN can provide stable and professional services.

Along with our advanced equipment, this deep field of expertise let’s us strictly control the manufacturing process; from material control to cutting precision to finished products. 90% of manufacturing processes are in house. Whether it is reverse engineering or customized gear products, MINCHEN can provide stable and professional services.